Climate and Sustainable Energy

A continued effort to reduce emissions

Our corporate climate ambitions were significantly strengthened in 2019 and have made considerable progress since then, contributing to the global targets for 2025, 2030 and ultimately net zero by 2050. These efforts include a commitment to reduce emissions and energy consumption across all aspects of the operation, which will make the organization more sustainable.

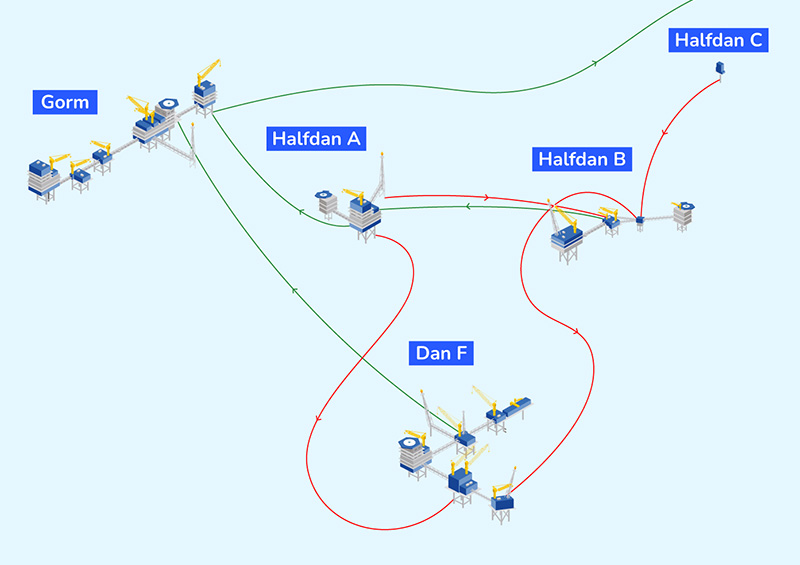

Many of DUC’s installations are interconnected on the seabed – in fact, more than 700 kilometres of pipeline ensures that the network of production, processing and transportation of oil and gas to Denmark runs in a reliable and responsible way. This means that activities and events on one facility can have an impact on multiple sites.

At the Gorm field, DUC’s oil production is processed and shipped to shore for distribution to the Danish consumers. In 2020, a project was initiated to re-route oil production from the Halfdan field to Dan F rather than Gorm. The aim was to reduce routine flaring. In 2023 we completed the second stage of the project and eliminated routine flaring from our operations.

Until 2017, the oil produced at the Halfdan field was degassed on Gorm Field and the gas was processed in a tandem compressor and then used as fuel gas. The 40-year-old compressor was designed for a production volume that was much higher than today’s level. The compressor was damaged beyond repair in 2017. The fuel consumption of the compressor and the compressor demand was similar, meaning that either the gas is burned as fuel gas in the compressor driver or a similar gas volume is flared routinely. The routine flaring solution was assessed to be the safest and most environmentally responsible in the situation.

In parallel, new regulations came into force in Denmark requiring routine flaring to end by July 1, 2023.

“Initially we thought that the timeline was a bit tight, and a more realistic timeline would be to stop routine flaring by the end of 2023. However, we made it a priority, allocated resources, accelerated the process, and managed to achieve our goal by July – just five days after the new regulation came into force,” says Susanne Frederiksen, Carbon Footprint Reduction (CFR) Manager.

In the case of Halfdan, a partial re-route was already initiated in February 2022, which reduced routine flaring by about half. The full re-routing, resulting in the end of routine flaring and a reduction of about 20,000 tons per year of CO2e emission, which is equivalent to a 50-kilometer commute by more than a million cars1.

1 Calculated using co2.myclimate.org.

Flare systems

Flare systems are installed on all oil and gas facilities to ensure safe disposal of excessive gas during operations and safety incidents. According to World Bank’s Zero Routine Flaring Initiative, the flare can be split into three categories.

Safety flaring: Flaring to ensure safe performance of operations conducted at the production sites (emergency shutdown, safety-related operations, etc.).

Non-routine flaring: Flaring other than routine flaring or safety flaring associated with oil production and occurring primarily during occasional or intermittent events.

Routine flaring: Flaring during normal production operations in the absence of sufficient facilities or adequate geological conditions permitting the

reinjection, onsite utilization, or commercialization of produced gas (as defined by the working group Global Gas Flaring Reduction program as part of the World Bank’s Zero Routine Flaring Initiative). Routine flaring does not include safety flaring.

20,000

tons of CO2e emissions per year reduced as a result of ending routine flaring on Halfdan after re-routing oil production.

30

percent lower CO2e emissions are forecasted on the new Tyra II compared to the old Tyra (verified emission levels from 2017).

Using drones for methane reporting

Several other projects led to improved emissions performance in 2023. Quantitative Leak Detection and Repair (QLDAR) was conducted regularly as well as on as-needed basis on all our operating installations using OGI (Optical Gas Imaging) cameras based on infra-red sensing technology. This in itself improved our reporting of fugitive emissions and resulted in a Greenhouse Gas (GHG) reduction of 22.3 ktons of CO2e for that year.

Drone surveys to measure methane and CO2 emissions were also repeated in 2023 after being conducted in 2022 on all our operating platforms and satellites as well as flares. Another initiative that contributed massively to improving methane reporting was detailed flare and vent source mapping. This was key to identify areas we can improve and initiate new projects for the purpose of methane reduction.

In 2023 we started the publication of a Carbon Footprint Reduction page on the TotalEnergies EP Denmark intranet and quarterly newsletters to offshore workers. These initiatives were to raise the awareness of all employees and contractors on and offshore. A local seminar was held to engage and share best practices and projects to reduce emissions.

Much can be achieved by a strong organization with a focus on delivery and awareness. “It’s a matter of prioritization and focusing on the strength of the organization,” Frederiksen says, looking back at the Halfdan re-route. “When we focus on a task, and put in the resources and commitment, we can react quickly and reach significant achievements. But it is a continuous balance between being on top of safety and integrity, and ensuring security of supply while at the same time reducing GHG emissions,” adds Frederiksen.

“It is a continuous balance between being on top of safety and integrity, and ensuring security of supply while at the same time reducing GHG emissions.”

– Susanne Frederiksen, Carbon Footprint Reduction (CFR) Manager

Energy efficiency on Tyra II

The redevelopment of the Tyra gas hub is the biggest offshore engineering project carried out in the history of the Danish North Sea. When the new facilities are fully back on stream, the largest gas field in Denmark will be able to deliver gas to Denmark and Europe with an optimized carbon footprint. Thanks to new design, high-tech equipment, new processes and optimization via more than 100,000 data points, the gas sent to Denmark is expected to have a production footprint of 12-16 kg CO2e per barrel compared to a current average of approximately 30 kg CO2e per barrel across our current North Sea installations. Total annual emissions (Scope 1) are forecasted to be 30% lower (approx. 315,000 tons) compared to 2017 before the production of the field was temporarily shutin, an outcome of lower production volumes and the optimized carbon footprint.

Helping suppliers to improve

Our efforts do not stop at our own facilities. We are also in dialogue with our suppliers on how to improve the footprint of the significant supply chain for our oil and gas activities. In 2023 studies and pre-projects were conducted to be ready for implementation in 2024 focusing on clean fuel and power for supply ships and helicopters.

Energy management certification

The Energy Management System of TotalEnergies EP Denmark was certified by an independent third party to comply with the ISO 50 001 Energy Management System standard in March 2023.

This ISO 50 001 standard provides a practical way to understand and improve energy use based on a system of continual improvement which makes it easier for organizations to integrate energy management into their overall efforts to improve energy efficiency.

TotalEnergies EP Denmark achieved this through a review and rollout of an updated energy management system, allowing for continuous improvement of energy performance, including energy efficiency and energy consumption.

Danish law requires regular assessment of energy consumption, and the ISO certification was selected as it is a good indicator of how we are doing and shows our level of commitment to emissions reduction.